| Eng | Rus |

About us

Industry

Our production

Technology

Dealer

Application for

need of product

Not realized

production

on our storehouse

News

Main page

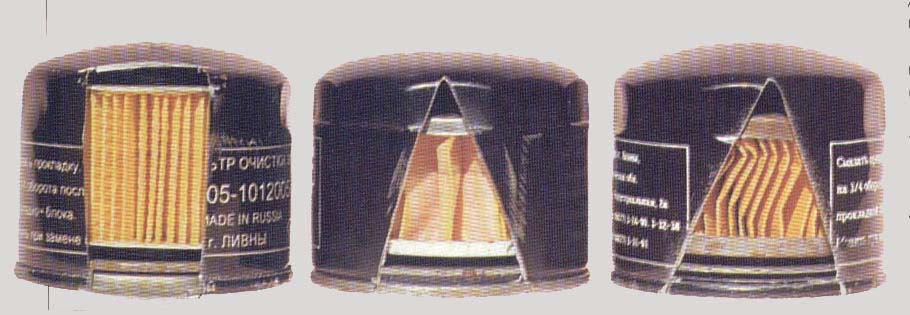

"AUTOAGREGAT" consists of two halfs-shop "VAZ" and shop "KAMAZ", but indeed, there are several shops . Filter, we take for example oil filter by "VAZ" 2101-1012005-20, "begins", like any other filter, in a press shop.

First that dashes in the eyes, though it'l be more exactly to say in the ears - is the noise. Though there is nothing offensive for plant -it is not worth expecting the cemetery silence from several tens of press machines in three floors. In a press shop the machines of japanese company AIDA work and, how we were announced by the deputy, work without any troubles. Here the body of oil filter is stamped, and then it is carried right in shop "VAZ".

There in this time an amplifier wait its queue ( the workers name so the flange - threading part of filter's body ), setting and drainage gates and filtering element itself. But we will say about everything in order.

Amplifier consists of two halfs, which unite by the point welding, and seam between them is oiled by hermetic mastic. In this time setting and antidrainage gates are stamped and gathered. As You remember, setting gate limits the pressure in system of lubrificant, and antidrainage serves for preventions of flowing oil from the channels, attending different mechanisms when engine stop (by GOST a hermeticity of antidrainage gate must be preserved at pressure in system of lubrificant non more then 0,3 m oil pole).

Now -about filter paper. As is well known, it executes the most main function of the filter. "AutoUnit" uses the paper of italian company "Aster". Certainly, there was the experience of using paper from other companies, in particular, german "Binzer", but choice laid on "Aster". In seventieth years, when it was difficult with "import" , our Herson's paper was used.

Filter paper must answer for variety of cruel requirements, in particular, It is obliged to miss strictly stipulated amount of firm particles, it must also bear definite load on breakup and has not to stratify on filaments. The part of paper's characteristics are downloaded when it's produced, the others are provided by preparing filter elements in the plant-producer.

The main moment in preparation of paper's blind for filtering element - paper's polymerization in the stove under the temperature 160-190degrees a Celsius. Before sending paper in the the stove it has to be cut on the ends and has to be corrugated. In polymerization process occurs the evaporation of linking resins, mutual fixation of filaments and opening of channels, which execute the sifting out strangers particles from oil flow. If paper will not be polymerisated or if You break the technology, then blind will simply stratified on filament, littering oil channel of engine. It is not worth to say about consequences. After stove corrugated and polymerisated paper enters on scrap, wraps around in ring and stick by the butt-end to the cardboard rings, forming filterring element itself.

The main moment in preparation of paper's blind for filtering element - paper's polymerization in the stove under the temperature 160-190degrees a Celsius. Before sending paper in the the stove it has to be cut on the ends and has to be corrugated. In polymerization process occurs the evaporation of linking resins, mutual fixation of filaments and opening of channels, which execute the sifting out strangers particles from oil flow. If paper will not be polymerisated or if You break the technology, then blind will simply stratified on filament, littering oil channel of engine. It is not worth to say about consequences. After stove corrugated and polymerisated paper enters on scrap, wraps around in ring and stick by the butt-end to the cardboard rings, forming filterring element itself.Hereinafter the most responsible moment occurs - final assembly and joining the amplifier with a body of the filter, so-called "zakatka" - the operation like actions with glass banks, in which different boilling and saltings are prepared to winter. The non painted filter goes to ÎÒÊ, where it is checked on special equipment on two parameters: on hermecity of amplifier, welded from two halfs (this is identified as "operation COLEX" at the factory) and hermeticity of joining the amplifier with the filter's body ( the filters are bolt in stands of the tool of the carrousel type, then these are immersed with the seamstress in the water, the air goes through the stands into the filter and non hermetic seam finds itself by the appearing bladders of the air).

If everything is in order - filter passes through the washing installation, its surface is phosphated for protections from corrosion and it enters to painting camera, where the marking is inflicted after drying on it. Painted filter are packed in the boxes and enter to the storehouse, where its wait the dispatch to realization.

Now we wil speak about possible forgeries of product JSC "AUTOAGREGAT". In particular, the "pirates" have choosed oil filters 2101-1012005-20 and 2105-1012005 from all assortment in Livny's plan.

Falsifications of these marks are really much resemble to persisting Livny's production, but it's absolutely disabled. They almost don't clear oil, but body can turn out to be not hermetic, growing even at working pressure in oil system. In result, such filters serve during 2-3 thousands km. instead of necessary 15. Though, knowing how the forgeries are printed it's possible to wonder.

Main filter's function - clearing the oil- is provided by the blind, maked from special paper. In pirate products the blind don't work almost always, although the reason for this can be different.

First of all - faulty paper. It's happened that in forgeries the quality paper are also used, even paper of leading world producer. But then they put in action other "spare" - they reduce the amount of paper in the blind, in two and een in three (!) times. Area of filterring surface sharply grows shorter, and such producer takes the pretty bet (the full-fledged blind from qualitative paper - it is 30-50% cost of the filter).

Now we address to other important element of oil filters -gates. In filters made in Livny for "VAZ'' there are two these- antidrainage (the counterowerflow) and setting. Sub-standard antidrainage gate forces the engine to work without lubrificant for 5-7 seconds at each starting, and fault setting not misses the oil to filterring blind or misses through itself unrefined oil when the engine works. In forged filters these defect are not trick.

Yet one trouble liing in wait for driver in forgery, - nonhermeticity or bad made body. Such things are impossible on the plant "Autoagregat". Now we will say about what is possible to see on the filter itself:

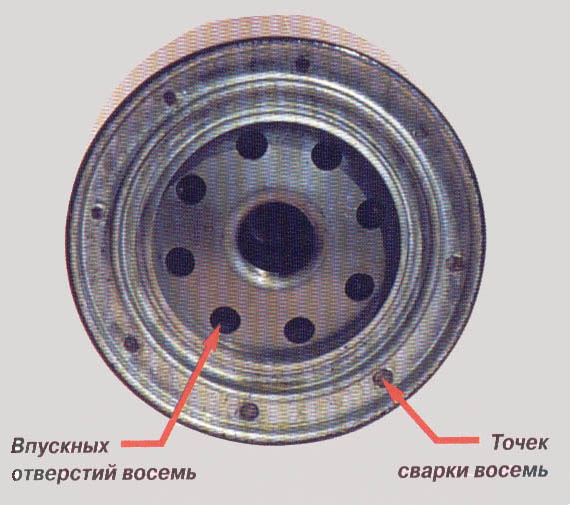

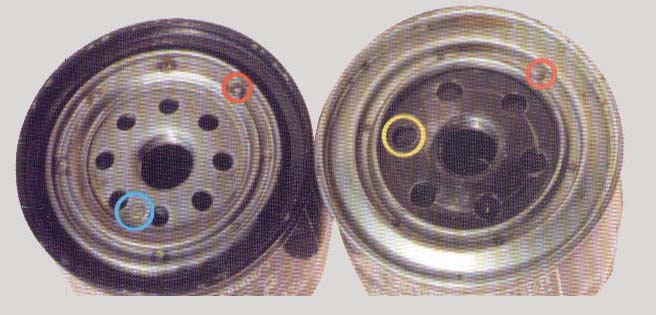

At First, the points of the contact welding are located on the amplifier between the sealing reserve ring and the butt-end. On the adulterated products its can be found often under the rubber sealant.

At First, the points of the contact welding are located on the amplifier between the sealing reserve ring and the butt-end. On the adulterated products its can be found often under the rubber sealant.Secondly, there are eight points of the welding on the authentic products,and there are six-on the forgeries.

In-third, in Livny's filters there are eight inlet holes, but in forged its number varies from four to eight ( more often it can be six).

In-fourth, there are no any gived signs- A,Z,Z, triangle, pentagon, hexagon and so on on the amplifiers of the authentic filters. Its can be met on the forgeries enough often.

Finally, in-fifth: the seam on the butt-end of Livny's products are painted together with a body. In forged filters the body is often painted apart whereupon the lid is being closed.

As to logotype and inscriptions on the body, the "pirates" learned to do its nearly jewelry. However there are also own nicety.

For instance LAAZ don't inflicts on their own filters any inscriptions on foreign languages except "made in Russia". There are no persisting Livny's filters with inscriptions made in Germani,made in Korea, made in Italy, made in USSR and so on.

Regrettably, the packing don't speak anything about producer. Other sellers having realized the party of the persisting filters, stuff the forgeries in Livny's boxes and continue to trade. Sometimes, several pieces persisting Livny's filters are putted in the box's high level on the event of spot check. And this is far from the full list of the cunnings.

There is yet one sign, about which it's useful to know. At the factory, each filter is folded in the paraffin paper, but forgeries, as a rule, are packed in the polyethylene or in usual paper. In general, the probability of buying forged filter is very great. On our facts, the market are simply infesteded by the forgeries. That's why in all events it's worth to use the requisitions of official dealers JSC "AUTOAGREGAT" when buying. The list is provide in section "Dealer" in our site.